Gateway 2 Masonry Support Design

A comprehensive design package to navigate the complexities of Gateway 2 projects

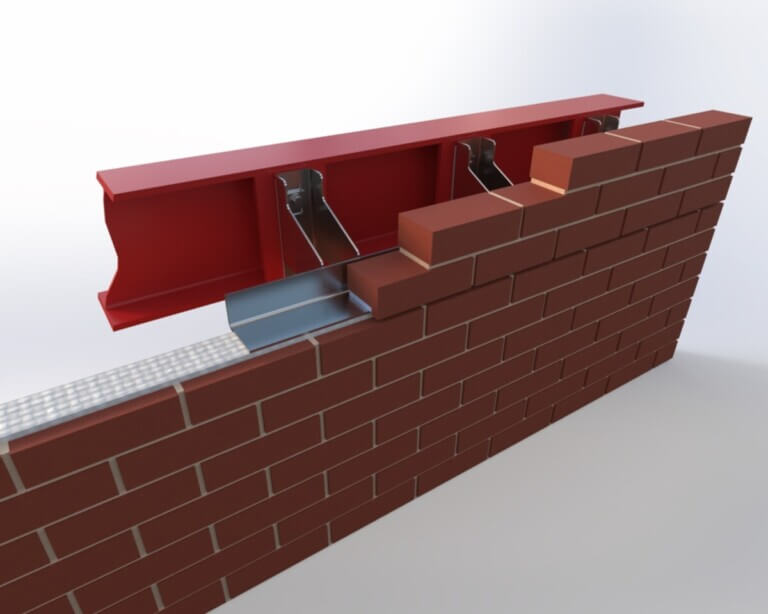

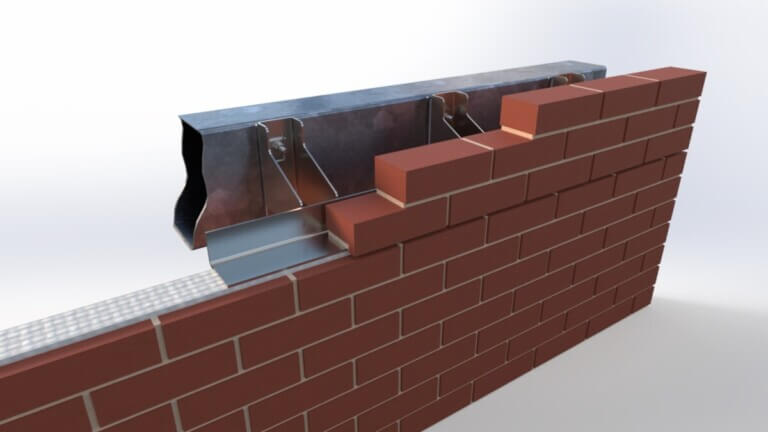

The FIRMA FMS masonry support system is compatible with a variety of cavity sizes, projections and loadings. Provided as a complete package including fixings, shims and thermal shims for ease of installation.

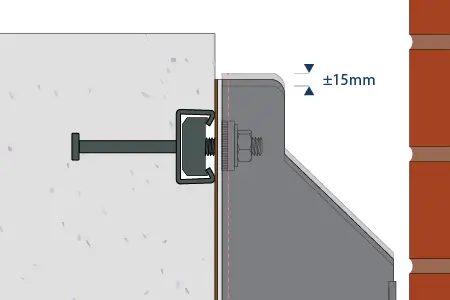

Patented locking washer system to allow for easy vertical adjustment of +/- 15mm.

The FMS System is compatible with cavities as narrow as 40mm

+/- 10mm of in-out adjustment to allow for variances in the fixing surface

There are 4 main fixing options for use with a Concrete Frame.

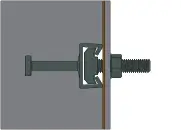

This is the most common fixing method used for masonry support. FIRMA offer 3 options depending on loading requirements; 40/223, 50/30 and 54/33

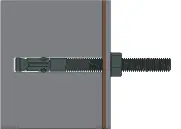

Also known as a knock-in or expansion bolt. These are the most common post-fix solution used with masonry support

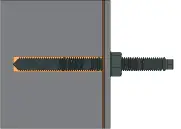

These offer higher pull-out resistance than mechanical anchors, so are ideal for poorer quality substrates, over-sized or irregular holes, and significantly high loads

There are two common options used for fixing masonry support to steel structures

This is typically used with a universal beam structure, where access to both sides of the fixing plate is possible

These are ideal for use where access to both sides of the fixing plate is not possible, for example with a hollow steel beam

There are a number of different types of concrete frame, however the fixing types are largely universal.

With a concrete frame, the masonry support system can be fixed in place either using the FIRMA Cast-In Channel systems, or post-fixed with site drilled fixings such as expansion bolts. This is specified in line with site specific structural requirements.

For steel frames, there are two main options available. Where it is possible to access both sides of a fixing surface, a Hex Screw (or Set Screw) is generally suitable. Where access is only possible from one side, for example with a hollow section beam, a Blind Bolt is usually suitable.

With masonry panel design, allowances must be made for differential movement between materials. This is particularly critical when combining clay brickwork with concrete blockwork and a concrete frame, as these elements expand and contract at different rates.

To accommodate vertical movement (typically ~1mm per metre), movement joints are generally introduced at every storey or every second storey. These joints are also commonly incorporated in buildings of less than four storeys to ensure long-term stability and façade performance.

Masonry Support systems should be installed directly above horizontal movement joints. These joints provide the necessary allowance for brickwork expansion below the support and for any shrinkage or deflection of the structural frame.

There are some points to consider:

Structural and masonry tolerances must be considered before finalising support design.

Standard systems offer limited tolerance, so adjustments must be built in prior to manufacture.

FIRMA Masonry Support Systems are manufactured from grade 1.4301 (304) stainless steel, suitable for most building applications. In particularly aggressive or visible environments, grade 1.4401 (316) stainless steel can be specified.

Bi-metallic corrosion may occur where stainless steel components are in contact with carbon steel in damp conditions. While the stainless steel is unaffected, the carbon steel may experience slightly accelerated corrosion.

To prevent this, the stainless steel support system should be isolated from the structural steel. This can be achieved using:

FIRMA provides isolation solutions where required to maintain the durability of both stainless steel and adjacent structural steel components.

FIRMA Masonry Support systems carry a UKCA certificate of conformity and are designed to the requirements of EN1993, Eurocode 3 and manufactured to the standard EN1090-1:2009+A1:2011 execution class 2. FIRMA Limited are also certified to ISO9001 and ISO14001 and internal monitoring is done through the FIRMA QC Portal and RopeWeaver prioritisation software.

The FIRMA FMS System is designed to our Made Simple® methodology. With this, we ensure that every solution we provide is engineered to be the most efficient and cost effective solution. As we apply this methodology to our masonry support design, we ask ourselves 3 key questions:

Yes, the FMS system can be used for a curved façade. If you have a project with a curved masonry façade, get in touch with our team – Contact Us

It will depend on a few factors, such as the slab depth, location of the fire barrier, and most importantly where the brickwork needs to be supported from. One example of why this may be specified over a standard system is to support the brickwork between full height windows, thus reducing the overall meterage of the masonry support.

For masonry support, the main factor that would determine this would be proximity to the coast, or any salt water. The usual rule is that if the building is within 500m of the coast or a body of salt water, the material should be 316 stainless. There are no specific regulations that apply to this, it is generally recommended.

Normally this would be the case. As the masonry support strategy is engineered, it is important to make sure that the position of the Cast-In Channel is coordinated with the masonry support fixing position. It may seem obvious, however this is not always considered for in the early stages of design, and can lead to very costly coordination issues during construction.

It is most common to support two floors of masonry per level of masonry support, however this is determined by a number of factors, including but not limited to:

Final capacity is always confirmed by project-specific structural calculations.

Masonry support systems are manufactured from non-combustible materials, mainly stainless steel, and therefore achieve the highest fire performance classifications. When correctly specified and installed, they are suitable for use on high-rise buildings and comply with relevant fire safety and building regulations.

The FMS Masonry Support system is designed to allow +/- 15mm vertical adjustment, and +/- in-out adjustment (to deal with slab edge variances).

The system is also designed with horizontal adjustment, with up to +/- 5mm adjustment in the toothed locking washer and a 10mm tolerance gap between each shelf angle. When installed with FIRMA Cast-In Channel systems, the FMS system has infinite horizontal adjustment.

Yes, the FMS system is compatible with our Brick Slip Soffit systems. Together these systems are designed as a bespoke solution for each project. Get in touch with our team to find a solution that works for your project by visiting our contact page

Please provide the information below to receive your bespoke Specification, typically within 1-2 working days.